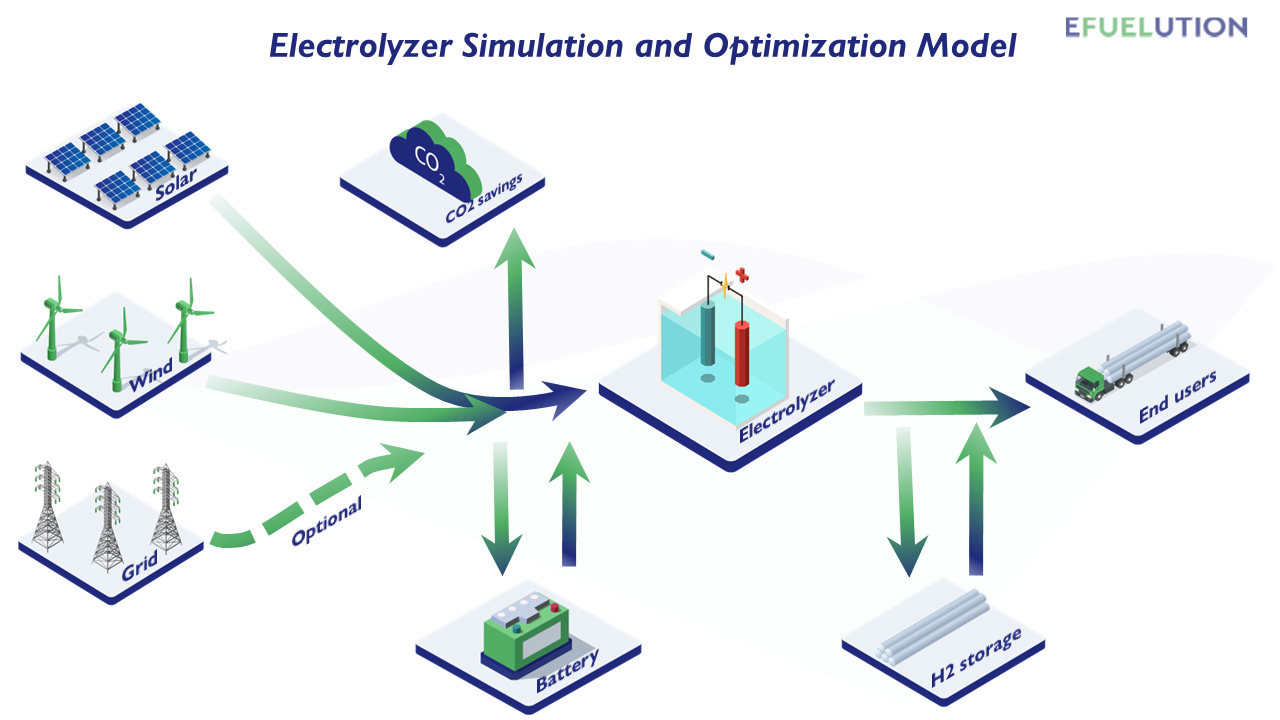

If you plan to produce hydrogen using your own electrolyzer, like many of our customers, you may encounter several crucial questions. How should you determine the appropriate size of the electrolyzer? What quantity of hydrogen will you produce in the future, and how much electricity will be required? Furthermore, how will you handle situations when there is no wind and the sun isn’t shining? At eFuelution, we provide solutions to these inquiries through our self-developed dynamic simulation model. Allow us to briefly explain how it operates.

A precise model for maximum efficiency and cost-effectiveness

During the initial stages of exploring the feasibility of a hydrogen production project, modeling plays a significant role. By incorporating the various components of a hydrogen production setup into a model, you can establish an optimal configuration. This approach ensures that your installation operates with the highest level of efficiency and incurs the lowest possible cost.

In collaboration with researchers from a university, eFuelution has developed several simulation models. These models are used to optimize the sizing of different components of an electrolyzer based on specific situations.

To begin with, our static model helps determine three key aspects globally:

- The amount of hydrogen required

- The amount of power needed from solar, wind, or possibly the power grid

- The approximate sizes of the electrolyzer, hydrogen storage, and potential battery

Concept development and feasibility study in an agricultural area

Agricultural areas offer ample space for solar and wind energy generation. However, electricity consumers are scarce and there is limited capacity on the electricity grid. Therefore, local hydrogen production is highly appealing. Find out how we achieve this.

Dynamic simulation: Knowing when to peak

With our dynamic model, we take a step further. This model provides a detailed hour-by-hour simulation of an entire year.

How does the system perform during periods of no wind or sunlight? How much electricity do we need from the grid, and what are the associated costs?

Is it advantageous to store excess energy using a battery? Should the electrolyzer operate continuously, or is it better to turn it off intermittently? How much hydrogen storage is necessary to ensure availability when needed?

By optimizing a production setup using our dynamic simulation model, you will find answers to these questions. The simulation also reveals the amount of CO2 emissions saved by the installation.

Enhance your electrolyzer performance

The dynamic simulation holds value for initial feasibility testing as well as the optimization of existing hydrogen projects, and everything in between. Contact us to explore your options.