Optimize your complete Hydrogen production value chain powered by wind, solar, grid or other sources

eFuelution launches their new simulation tool: Hydrogen Simulation Model 3! Building on the experience with the previous versions, Hydrogen Simulation Model 3 provides deeper insight in your hydrogen production chain from power source to hydrogen delivery. The model is business centric aiming at analyzing and optimizing the production chain to a minimum cost of hydrogen.

Why simulating your Hydrogen production chain?

- Risk-free environment. Simulation modeling provides a safe way to test and explore different “what-if” scenarios. Make the right decision before making real-world changes.

- Save money and time. Virtual experiments with simulation models are less expensive and take less time than experiments while engineering.

- Insight in dynamics. Unlike spreadsheet analytics, simulation modeling allows observation of system behavior over time at any level of detail. E.g., you can check electrolyzer utilization at any given date & time on an hourly timescale.

- Increased accuracy. The simulation model captures much more details than an analytical model, which provides for increased accuracy and more precise forecasting.

- Handle uncertainty. Simulating ‘what-if’ scenario’s allows you to mitigate risk and find more robust solutions.

Features of the Hydrogen Simulation Model 3

- All power sources. If the electricity for the electrolyzers is provide by wind, solar, the grid or any other means, it can be modelled. Wind, solar & grid are pre-programmed.

- Complete chain modelling. From electricity source to hydrogen delivery, the whole chain is dynamically modelled and optimized. This includes hydrogen compression, transport &storage, offtake patterns and a battery system if required.

- Global coverage. The models automatically sources global wind and solar profiles. Just provide the location, anywhere in the world, onshore or offshore.

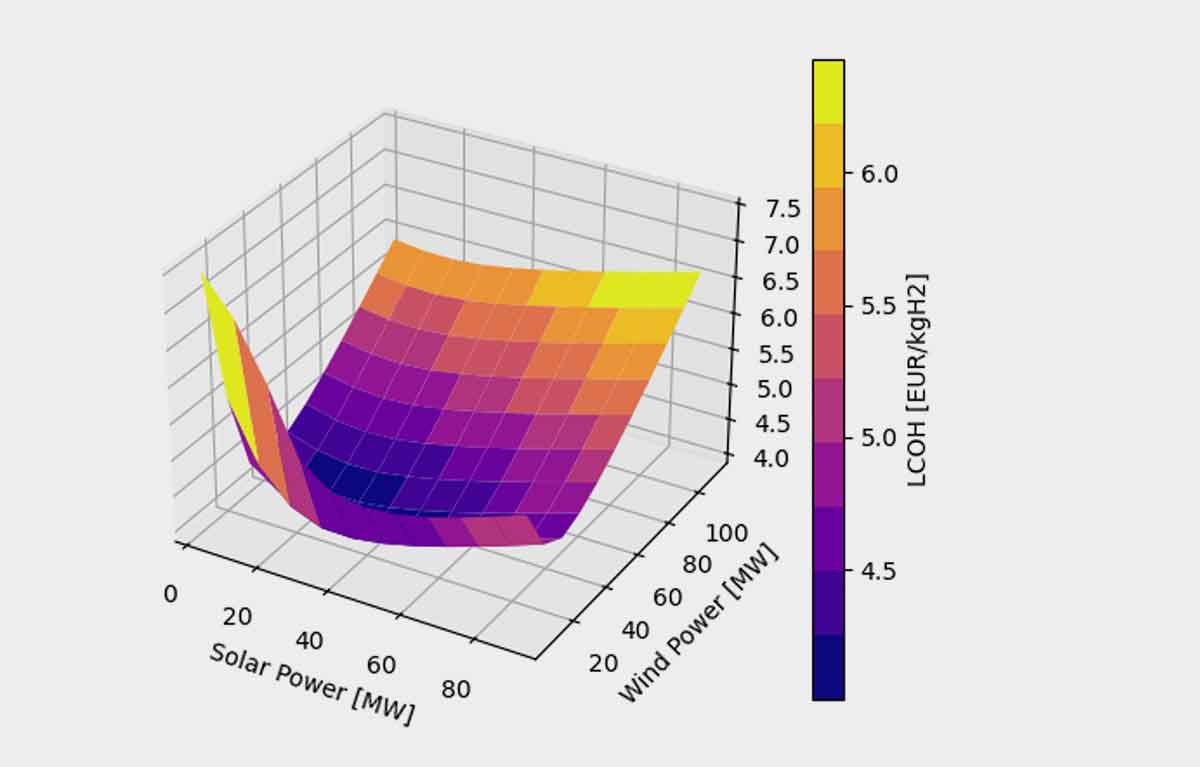

- Graphical presentation. All simulation data can be shown in 2 or 3 dimensional graphs on any time scale. This provides deep insight in the dynamics of the simulated H2

- Business Centric. Based on either generic Capex and Opex data or on specific equipment specifications, the model can optimize to any desired parameter, such as the minimum cost of hydrogen (LCoH) or maximum amount of hydrogen produced.

- Client-specific. With boundary conditions set by the client, such as geographical or spatial limitations, the model can come to an optimal value chain setup based on the desired output by the client.

Interested how we can improve your hydrogen project by applying our Hydrogen Simulation Model 3?

Please contact Jan Thijs Maatman at Maatman@efuelution.com or +31 6 50 12 84 21.

#eFuelutionSimulationModel3 #Hydrogenvaluechain